Preamble

The underfloor heating concept for residential and public environments is very ancient and independently emerged in different civilization, even though very far from each other either on a geographic or a cultural standpoint. A thorough overview regarding the use of radiant underfloor heating techniques is provided by the paper “Radiant Heating and Cooling Systems” (reff. [1] e [2]) divided in two parts: part 1, devoted to Asian and Far East countries, and part 2, devoted to European and Mediterranean countries. Additional historical quotes are provided by some Caleffi’s excellent papers (Idraulica 9, ref. [3], Idraulica 21, ref. [4] and Quaderno 4, ref. [5]), some web-sites [(1), (4), (6), (7), (9), (33), (34)], and some specialistic handbooks like reff. [13] and [15].

The historical evolution of the underfloor heating may be effectively subdivided into six periods of different duration each one characterized by a substantial homogeneity of application (see also Caleffi, ref. [5]).

Ancient Times

As mentioned in the above preamble, the underfloor heating system, in residential and public environments, was in use many years before Christ in different geographical areas: in Asian Far East, China and Korea, up to Aleutian Islands; and in Mediterranean area, in Greece and Rome.

According to Bean et al. (ref. [1]), the first rudimentary underfloor heating systems (the “kang”, which in English means “heated bed”) started to be in use in China around 10.000 B.C. About 5.000 B.C. more advanced systems were widely in use in China (the “dikang”, meaning “heated floor” in English) and Korea (the “ondol”, which in English means “warm stone”) [see also site (1)]. In Imperial China, the use of the heating floor technology continued with no dismission up to 1.910 A.D. being subjected to gradual refinements and improvements as the implementation of channels not in contact with the soil to reduce thermal dispersion and the external ubication of the furnace. About 1.000 B.C., the use of this heating system was widespread in North-Korea and extended up to Aleutian Islands (Alaska).

The archeological findings show that, initially, the floor was heated by a furnace located directly beneath it (in “kang”, “dikang” and “ondol”). The furnace was initially used either for heating or as primordial oven to cook food. Later, the cooking function was separated from the heating one, moving the oven to the external perimeter of the homes (Figure 1 ÷ Figure 4).

According to the websites (2) and (3), even the Egyptians used the underfloor heating technique, but no paper among those consulted has confirmed this information. As per the website (3), the technology used by Chinese and Egyptians was not so much developed since based on a brazier just beneath the floor, which as seen is a solution that the Chinese used only for the oldest constructions, as it can be inferred by the following images.

Figure 2: Reconstruction of a Korean Ondol with cooking and living sides [source: site (11)]

According to the website (1), Greeks and Romans begun to use the underfloor heating system about 500 B.C. The website (4) dates the use of this heating system since 2.000 B.C. in Greece.

Regarding the dates, there is, however, some uncertainty and confusion, considering that the “Hypocaust – Wikipedia” page [site (5) >>] conversely states that some Greek hypocaust findings date back to 100 B.C. (Cladeo’s Baths in Olympia) and Romans attributed the invention of this heating system to Gaius Sergius Orata (ref. [7]), a Roman citizen from Lucrino (140-90 B.C.), coeval to Cicero. This attribution, even though frequent, is not considered correct by all authors, since in contrast with the known fact that the ‘’hypocaustum’’ was already in use since time in Greece. More probably, Orata was the one who conceived the steam bath, i.e., the sauna [source: site (6)]. In paper ref. [2], Bean et al. state that the hypocaust was introduced in Europe in the third century B.C., referring not only to the above-mentioned Gaius Sergius Orata, but stating also that findings of the system have been found in Greece (Gortys) and Magna Graecia (Gela, Megara Hyblaea, Syracuse) dating back to third century B.C. The same source highlights that from Rome the hypocaust spread toward East, in Afghanistan (ref. [8]) and Syria (ref. [9]), and to South, in Africa (ref. [10]).

Greeks and Romans applied the same principle independently used by Chinese and Koreans. Furnaces ubicated below the floor elevation, either internally or externally the building perimeter, were heating the air flowing inside channels connected to the lower surface of the floor slab. This underfloor plant was named “hypocaustum”. The ‘’hypocausts’’ (from Latin hypocaustum, a word that in Greek means “heating from below”) were made of a series of galleries underneath the floor slab, which got the name of “suspensura”, since not in contact with the soil but supported by brick pillars (pilae in Latin). The air, heated by an external or internal furnace (hypocausis o praefurnium), generally fed with charcoal, was flowing through the underneath cavity so obtained. The same system was used in the Roman Thermal Baths. Here, the heated air, upon licking the floor, were conveyed to a duct (the vaporarium) from which entering the so-called «parietes tubulati», i.e., tubular cavities made in the wall bricks, aimed at heating the above dwelled rooms. The cavities underneath the suspended floors (suspensurae) were about 50-60 cm high. It is supposed that the temperature inside the inhabited rooms should be not above 30°C [source: site (5)].

The design of the thermal bath hypocausts reached a good level of standard practice as it is proved by Vitruvius who, in his “De architectura”, listed all requirements to be met [site (7)], which are recalled by the webpage Hypocaustum of Wikipedia which quotes a passage, written in Latin, of the «Vitruvius de hypocausto aedificando» [site (8)].

Ref. [11] and website (6) provide many interesting images of Roman hypocaust. Some of the most significant images are shown below.

Figure 5: Hypocaust of a Roman Thermal Bath [source: site (4)]

|

Figure 6: Hypocaust of a Roman Thermal Bath [source: site (1))

|

|

Figure 7: Roman Hypocaust [source: site (2)]

|

Figure 8: Heated air distribution in Roman Thermal Baths [source: site (3)]

|

|

Figure 10: Hypocaust in Roman Villa at Saldata [source: site (5)]

|

Regarding the furnaces, the hypocausis a word that in Latin means “underground heater”, it is noted that a set of interesting images are shown at the following link (>>).

Even though widely used in the Roman world, the hypocaust system did not survive the medieval transition and disappeared from architectural use of the next centuries, at least in Europe where it was replaced by wall heating through braziers or fireplaces, then stoves. On the contrary, Korean ondol continued to be used up to modern times, being improved and spread up to Japan too (ref. [2]). The hypocaust system continued, however, to be used in the Ottoman Empire for Turkish Bath heating [site (34)].

It is of interest that, about 1540 A.D., a radiant cooling system was implemented for the first time in India, through wall piping within which cold water was being flown (Lotus Mahal, Hampi, Karnataka) [site (34)].

From Seventeenth to Nineteenth Century

As reff. [2] and [17] state, the underfloor heating used by the Romans was resumed at the end of the seventeenth century.

Bruegmann, author of the paper ref. [17], mentions a 1691 book “Kalendarium Hortense, or the Gard'ners Almanac“ (ref. [18]) by John Evelyn (1620-1706), which, at page 137, highlights that a hypocaust heating system, heritage of the ancient times, was commonly used in Russian greenhouses, supporting that such system was certainly in use for greenhouses in Europe as well. The technique so rediscovered was since then, even though occasionally over the XIX century, implemented in new buildings, especially the public ones. The fire hazard was, however, a serious concern against a wider implementation.

In the Eighteenth’s there is memory of the use of a hypocaust system to heating the public baths (Hammam) in Erbi a town in Mesopotamia (today Iraq).

The volume 1 of the «Encyclopédie méthodique d’Architecture» (ref. [19]), of 1787, from page 631 to page 640 under the term «Cheminée» deals with the Roman hypocaust; in particular, at page 638, section «Des cheminées chez les modernes» underlines that in Europe this technique was no more used.

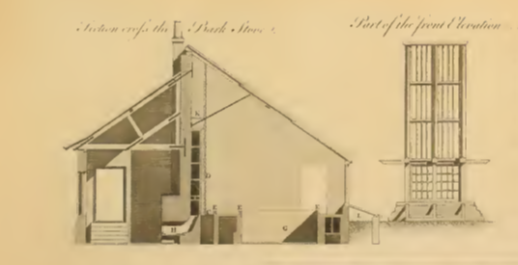

The English Architect William Chambers (>>) in his «Plans, Elevations, Sections and Perspective Views of the Gardens and Buildings at Kew in Surey», London, 1763 (rif. [20]) describes and outlines (plate vii) a XVIII century greenhouse being heated with warm gas flowing through the volume below the floor and then conveyed outside through ducts inside the back wall (Figure 11).

Figure 11: Section view of the cottage designed by William Chambers having the hypocaust system (ref. [20])

In 1792-93, the English Architect Sir John Soane (>>) – not Stone as read in reff. [2] and [13] page 9 – used the hypocaust system for the Bank of England heating. The following pictures, drawn by the collection «Sir John Soane’s Museum Collection Online» (>>), show: the left one, the piping underneath the hall floor with warm air and smokes flowing inside; the right one, the vertical ducts.

Figure 12: Hypocaust heating system designed by Sir John Soane for the England Bank [source: Collections.soane.org]

|

Figure 13: Hypocaust heating system designed by Sir John Soane for the England Bank [source: Collections.soane.org]

|

Hypocaust systems were considered also by the Botanist John Claudius Loudon (>>) who, in his «A Manual of Cottage Gardening, Husbandry, and Architecture», London, 1830 (rif. [21]), proposed a cottage heated following the hypocaust principle.

Edwin Chadwick (>>) proposed this technique (indicated as «Roman hollow floor») in his «Sanitary Principles of School Construction», Journal of the Royal Society of Arts, XIX, 1871, pp. 856-860 (ref. [23]).

Douglas Strutt Galton (>>) described how implementing this technique in the hospitals in his «Healthy Hospitals», Oxford, 1893 (ref. [24]): in the Herbert Hospital the hot smoke was channeled inside the cavity formed by two iron plates coated with two thin layers of refractory clay and then conveyed to a vertical duct for discharging. As recalled by Dufton (ref. [14]), Galton paid great attention to the aspect of healthiness of dwellings. He was the author of the book “Observations on the Construction of Healthy Dwellings” where one of the topics was the need of an adequate ventilation independently from the windows (rif. [63]).

William E. Ward (>>) in the paper «Béton in combination with iron as a building material», ASME Transactions, IV, 1882-1883, 396 (ref. [25]) described the pioneering construction of the Ward House at Port Chester (Connecticut) where hot smoke flew between two concrete slabs (fig. 2 of the mentioned Ward paper) to which the gas were conveyed by channels in the walls (Figure 14).

Beyond the pioneering implementations above described, in this period the improvements in scientific knowledge created the conditions for the next step forward of the underfloor heating method which since then progressively widespread, even though with no continuity of success, up to the present days.

In the Eighteenth Century, about 1741-1742 [site (24)], Benjamin Franklin, upon having studied the heating systems used in France and Asia, designed a stove having a high radiating capability taking advantage of an extended internal circulation of the smokes. The stove got the name of “Pennsylvania Fireplace”, but was later known as “Circulating Stove” [site (42)], or as “Franklin Stove” (ref. [2]), even though popularity was achieved after David Rittenhouse resolution of the several problems of the original Franklin’s design [site (42)]. The Rittenhouse improved design became the preferred heating system in American houses. The Franklin stove was characterized by a high energetic efficiency, since it could release twice the energy as per the same burnt charcoal quantity or, according to ref. [14], with this fireplace no less than five-sixths of the fuel required to heat a room could be saved. This stove, even though sharing with the underfloor heating panels only the radiating principle through a long channeling, is recalled as a milestone in the history of the radiating panels (see for example ref. [2]), even if there were other fireplaces not less famous, sometimes better working and not less interesting for the implemented physical principles such as: Galton’s ventilating fireplace, Gauger fireplace, “cheminée de Nancy” (see ref. [14]).

In the Nineteenth century the research on radiation and thermal conductivity allowed Angier March Perkins (>>) in 1839 and in 1841 to patent the first systems using the heat exchanged by hot water circulating in a piping. Angier March Perkins was son of Jacob Perkins (>>) considered the father of refrigerators and the inventor of an ingenious high pressure hot water systems (ref. [14]).

In this period, the water circulation in piping was used for room cooling in Europe and America, too, as already implemented in India since 1540 AD.

Years 1900-1945

The twentieth century began with two events that resulted in a real breakthrough for the future use of the underfloor heating technology. First, the Liverpool Cathedral, whose construction started in 1904 (>>), was equipped with an underfloor heating system making use of warm air. As discussed in ref.

[2] , it represented the largest modern implementation of an underfloor heating system with warm air (>>) circulating through a system of ducts formed under the floor or in the walls (ref. [13] , page 100). G. N. Haden & Sons (>>), who patented this system, named it as “Romana method of heating” (ref. [13] , page 8). Figure 15 shows some sketch of this construction.The decisive turning point for the use of the underfloor heating method was, however, made possible by the second event: in between 1907 and 1908 (ref. [13], page 9), Professor Arthur H. Barker developed the first design of a heating system made of radiating panels where hot water was circulating in small bore pipes embedded in concrete (ref. [13], page 8, and ref. [2]) whose efficiency he positively had tested.

The consulted sources do not provide concurrent information regarding these two events. Site (23), for example, credited Barker for the Liverpool Cathedral heating system, while Adlam (ref. [13], page 8) claims to be himself not Barker to have worked on this project; in ref. [5], Barker surname is changed into Baker. For site (11) Barker invention occurred in 1907, the same year where Frank Lloyd Wright showed a great interest in this heating method, further to a journey in Japan had in 1905, where he had discovered the “ondol” system. The ASHRAE presentation ref. [26] supports either the early interest of Wright or 1907 as date for Barker invention.

It is not quite easy to achieve through internet additional information on Prof. Arthur H. Barker. The Google search with keywords “Arthur H. Barker” (>>) provides, at first ranks, two Wikipedia pages devoted to a homonym American criminal, but no page for the thermal technician expert. Only as second rank outcomes, it is possible to discover the document “Arthur Henry Barker - Obituary” (ref. [27]), which provides details on Barker’s life and scientific career. We so learn that, in 1907, Barker achieved the English patent BP 28477 [site (16)] for his panel floor or wall heating system with hot water circulation inside. This system was patented in the USA too, in 1928 (US1671568 ref. [31]) and 1930 (US1775152 ref. [32]). It is however singular that in Barker’s fundamental handbook on heating “Barker on Heating – The Theory and Practice of Heating and Ventilation” published in 1912 (ref. [28]), this system was not mentioned at all. Barker is almost generally considered the father of radiant heating (ref. [27]), even though there is people who assign this primacy to Frank Lloyd Wright [site (26)], or a certain Irwin Jalonack indicated by site (27) as the father of radiant heating in the United States. It is to be noted that Barker got worldwide fame for the following books that had nothing to do with heating and thermal exchange: “Graphical Calculus” published in 1902 (ref. [29]) and “Graphic Methods of Engine Design. Including a Graphical Treatment of the Balancing of Engines” published in 1897 (ref. [30]).

Patent BP 28477 – no detail of which has been possible to discover on the web – according to site (16) and ref. [5] was sold to the “Crittal Company” about which they provide no additional info. The Google search shows that the “Crittal” (with one “l”) Company never existed. Ref. [2], indeed, clarifies that it was the “Richard Crittall – with two “l” – and Co Heating, ventilating and air conditioning engineers” which, as shown by the handbook ref. [15], attended to the heating system construction for a school in Amsterdam (Figure 3-8 of the handbook) and the Ranworth School in Liverpool (Figure 3-10 of the same handbook). Also, ref. [3] quotes this event adding that “Crittal” applied the system for the first time in 1909 in Liverpool, while ref. [5] (issued once again by Caleffi) claims that the patent purchase occurred in 1909 in London where the company applied the patented system for the heating of “Royal River Palace” (name that we’ll show later is wrong as well as wrongly localized). Each author seems to follow his own historical path, that is not ever able to pass a more careful historical investigation.

The website (35) informs that the “Richard Crittall and Co” in 1911 applied its panel radiant heating system, along with a ventilating system with cold air, in the “Royal Liver Building” in Liverpool. The current name of the company is “RCM Products” (>>) whose website provides the same info called here above.

Around the end of the thirties, especially due to Frank Lloyd Wright, the American real-estate developers began to make increasingly use of heating plants based on pipes embedded in floor concrete slab, which is substantially the same technique used today.

In 1937, Wright [site (30)] made use of the radiating panels heating system for the “Johnson Wax Building” and developed the design of the “Herbert Jacobs House” (ref. [26]), the first Usonian home [site (29)]. In 1940, according to “Architectural Record”, in the United States radiating panel plants were installed in eight constructions: four residential buildings, one church, a high school, an office building, and an aircraft hangar.

The paper “Radiant Heating in the U.S.” by Joseph F. Kern Jr (Heating and Ventilating, Volume 38, Number 3, March 1941, >>) lists as much as 84 implementations of the radiant heating along with additional 14 currently under design, in 1941. This issue of the magazine presented also a paper describing how the radiating system was being implemented in England.

Up to the end of the second world war, the use of radiating panels method was restricted to the cases above, with a predominance of nonresidential buildings such as schools, offices, and churches.

Years 1945-1970

Another prominent figure in the history of radiating panel plants was the United States real-estate developer William Levitt [site (31)] who, since 1945 to 1951, built seven large scale suburban residential complexes, known as “Levittown” (ref. [26]) [site (32)], having homes equipped with copper pipes embedded in the floor concrete slab, conveying hot water. In 1951 Levitt’s homes that were built following this principle were as much as 17 447 (ref. [26]).

The handbook “Radiant Heating” by Richard Woolsey Shoemaker, published in 1948 (ref. [15]), describes many implementations of this system performed by various manufacturers some of them still operating, even though with a different name. The list includes: Ames Aksila, B. S. Tilney, Robert Bruen & Son, Chase Brass & Copper Co. Inc. (>>), Bethlehem Steel Co (activity ceased in 2003 >>), A.O. Smith Corporation (>>), A.M. Byers Company (merged in 1970, >>), Richard Crittall & Co. Ltd. (presently RCM Products >>, see also site >>), Allen Copper Coil Manufacturing, The H.B. Smith Company Inc., Crane Company, The Timken-Detroit Axle Company, Penn Boiler and Burner Mfg. Corp., Delco Appliance Division General Motors Corporation, Gilbert & Barker Manufacturing Company, Iron Fireman Manufacturing Company, Bell & Gossett Company, H.A. Thrush & Co., Taco Heaters Inc., Sarcotherm Controls Inc., Johnson Service Company, Minneapolis-Honeywell Regulator Company, Hoffman Specialty Company, National Supply Company,

In 1950 also the real-estate developer Joseph Eichler (>>) adopted the floor heating technology and applied it to thousand homes in California.

Since the beginning, the radiant floor heating system went together with the radiant ceiling cooling method (ref. [26]). This last method, however, initially was not so successful because of condensation and mold, a problem that was resolved only using a specific ventilation system able to reduce the dew point of the indoor air. The so modified radiant cooling method was successfully applied in a store in Zurich (Switzerland), erected in 1936-37, and a multi-storey department store in Canada, built in 1950 (ref. [26]).

In 1951 the “United States Steel” published the Technical Bulletin “Radiant Heating with National Pipe – Bulletin n° 19” whose 72 pages provided details of the technical advantages of this heating method (>>). Similar technical bulletins, even though sometimes less detailed, have been already published by other companies such as: “Bell & Gossett” in 1945 (ref. [35]) and 1947 (ref. [36]), by “Chase Brass & Copper Co” (1950, ref. [43]), by “Copper & Brass Research Association” (1949, ref. [39]), and by “A.M. Byers Company” (1944, ref. [41]).

According to Caleffi (rif. [5]), in these years we assist to a surge in the application of the floor heating method, having been constructed in Europe more than 100.000 homes equipped with radiant floor heating panels. The construction technique was based on steel pipes (typically ½” but also ¾”) directly embedded in the concrete slabs, with no interposition of any insulating material. This solution resulted of great interest to the constructors being less expensive than wall radiators, since requiring a reduced number of operations on the walls, finishing operations were not hindered, the final painting could be waived.

Figure 16: Schematic of a floor heating plant in the fifties (source: Caleffi, Idraulica 9, ref. [3])

|

Figure 17: Floor split with old solution tubes [source: site (15)]

|

Caleffi (ref. [5]) reports the advantages as described by the Technical Bulletin n. 26 that Dalmine issued those years: (cit.) “1. Lesser cost of the radiating equipment, due to the fact that 11 m of ½” pipe radiate as a wall radiator of 1 mq; 2. Laying the pipes is quicker than mounting the wall radiators; 3. No masonry activity alike drilling or installing the wall radiator support anchors are necessary; 4. Neither in sight anchors nor radiator painting is required so that the finishing operations are not hindered; 5. In case the partition walls have to be moved, no operation on the heating plant is required.”

The economic benefits so envisaged, however, were not corroborated by a thorough analysis of the performances of these plants, mainly because of the reduced number of applications since then. These analyses were inevitably conducted further to the elevated number of applications in these years and the problems that began to arise. It happened, indeed, that soon people living homes equipped with floor heating system began to complain about a series of disorders spacing from headache to legs swelling, to excessive sweating.

Because of the high number of complains, some medical commissions were appointed to investigate over the lamented disorders. According to Caleffi (rif. [5]), three main causes were identified:

1. Excessive floor temperatures, due to the lack of piping insulation.

2. High thermal inertia of the floor since the panels (having no insulation) were heating the whole slab.

3. Not adequate regulation, practically only manual.

According to other authors, because of the lacking thermal insulation of the building envelopes [site (33)], an acceptable room temperature could be reached only by increasing the floor temperature up to 38-40°C, whilst the medical commission works had proved that an unwell condition arises when this temperature exceeds 28-29°C. The U.S.S. Bulletin n° 19/1951 (whose coversheet is shown in Figure 20) proves that in 1951 there was already a full awareness of these limits; really, at pages 11 and 28 of ref. [33] (>>), the prescription that the floor temperature would be within the range 75°F (24°C) through 85°F (29°C) was given. Because of the great thermal inertia of the slabs, the stored heat, while contributing to preserve the environmental temperature when the plant was not in operation, at the same time contributed to keep longer the high floor temperature.

Figure 18 and Figure 19 show the coversheets of the brochures that the company “Bell & Gossett” published in 1945 and in 1947. It is of interest to note that the new technology was presented with the wordings “Sun-like warmth” (1945) and “Capture the Sun” (1947)! This heating method was perceived and presented as natural as the sun energy is. The further evolution of this method will show that these slogans were not so far from truth, provided that the radiant heating and cooling technique (presently converged in the modern TABS) is today associated to systems with low enthalpy and high sustainability.

Figure 18 – Cover “BG Hydro-Flo Radiant heating” - BG, 1945

|

Figure 19 – Cover “Capture the sun with BG Hydro-Flo heating” - BG, 1947

|

Regarding the issue of the regulation and its (presumed) inadequacy, it is interesting to note that ref. [34], issued by Honeywell in 1946 (its coversheet is shown in Figure 21), provides a thorough and detailed discussion on how implementing the automatic control for these plants taking into account the various effects, including the thermal inertia. This analysis leads to a systematic approach for the automatic regulation. The Caleffi’s statement, in rif. [5], that the regulation was only manual is not confirmed by the quoted Honeywell publication (ref. [34]), even though there is no doubt that it was affected by the reduced application experience acquired until then.

In the United States many of the heating systems that Levitt built were out-of-service in 15 – 20 years, due to lack of thermal insulation, interaction between copper piping and concrete slabs, oxygen permeation and consequent corrosion of metallic parts triggered by it, the need of a more developed regulation [site (24)].

All these problems contributed to the bad reputation that quickly affected – in the United States especially – the radiant heating technology implemented in the fifties. That happened even though it was clear that the negative effects were not related to the principle but to the way it was implemented that did not consider the peculiar properties of the system. The medical commissions did not express any concern on the principle, but on the practical implementation only.

For these reasons, in the seventies this heating method was abandoned in the United States, while surviving in the Scandinavian countries and in Middle Europe where, since the Levitt times, the use of plastic tubes in lieu of copper piping was started. The Swedish company Wirsbo (that in 1968 became Uponor >>), founded in 1620 as a steel weapons manufacturer and later moved to steel tube manufacturing, by the fifties began manufacturing polyethylene tubing.

Figure 20 – Cover “Radiant Heating With National Pipe” – Bulletin n° 19 – USS, 1951

|

Figure 21 - Cover “Automatic Control of Radiant Panel Heating” - Honeywell - 1946

|

In these years (in 1951 exactly), Dr. J. Bjorksten of Bjorksten Research Laboratories in Madison, WI, completed testing (which covered the last three years) of three types of plastic tubing for radiant floor heating: polyethylene, vinyl chloride copolymer, and vinylidene chloride. In 1953 near Edmonton, Alberta (Canada), the first Canadian polyethylene plant started the operations. Polyethylene so began to be used for radiant floor heating, finally becoming the most – if not the exclusively - used material for this purpose.

In 1960 an NRC researcher from Canada got the decision to install underfloor heating in his home using water heated by a furnace fed with anthracite, anticipating the modern concept of sustainability, being his home identifiable as a solar passive house (ref. [37]).

In 1965 Thomas Engel patented the method for stabilizing polyethylene by cross linking molecules using peroxide (PEx-A). In 1967 he sold license options to several piping manufacturers. These two last events gave a decisive impulse to use polyethylene in these plants.

During this period, radiant panels were eminently used for the ceiling cooling (ref. [26]). “Alcoa Building” in Pittsburgh in 1953, “Kaiser Building” in Oakland in 1960 and “Shell Centre” in London (27 storeys) in 1962 are three examples of application of this method.

Years Seventies through Nineties

In the fifties in Korea an event took place that should have later great impact on the development of improved solutions for floor heating. The Korean war pushed people to change the material burnt in “ondol”, going to use cheaper coal in lieu of expensive wood. The use of coal, however, resulted to be disgraced when, in the seventies, Korean developer oriented to multi-storey buildings, each floor of which being equipped with its own furnace. The high quantity of coal combustion gases circulating in these buildings caused a so high number of fatalities to push the authorities to revise the concept and move toward the use of a centralized furnace. In this way the transition to more evolved and safer systems had the start.

During the seventies, the mix of better manufacturing techniques (using isolating material underneath the tubes and advanced regulation systems) and new norms on reduction of energy consumption, mainly because of the energetic crisis of that period, favored a rediscovery of the radiant panel method, which gradually gained greater success despite the bad reputation got for the past failures.

The improved insulation of the building envelopes, required by the new sectorial norms, allowed to reduce the water temperature below the threshold of 28-29°C, with the result to increase the comfort and, at the same time, reducing the floor slab thermal inertia (which is proportional to temperature), also in force of laying underneath the tube a layer of insulating material. These simple measures were sufficient to emphasize the benefits provided by the floor heating system.

The first European norm on floor heating was issued in the eighties. At the same time, the Korean “ondol” after having passed to a centralized furnace began to use hot water instead of combustion gases. In the mid-eighties the floor heating method became the reference system in Middle-Europe and North-Europe, even because the PEX technology got a further step forward with the adoption of a fabrication method able to create a barrier against oxygen permeation, that allowed to stop corrosion as occurred in the past applications.

In the mid-nineties the TABS (Thermal or Thermally Active or Activated Building Systems) were introduced into the market for controlling the climatic conditions in residential and commercial environments, by means of radiating pipes embedded in the concrete floor slabs, ceilings and in the walls, and circulation of fluids (water) having temperature close to the ambient one (reff. [52], [53], [54]) [sites (47), (48)].

The Noughties

The erection solutions adopted in these years led to the definitive success of the radiating panel plants, whose utilization became usual also because of the increasing adoption of low enthalpy generation systems (condensation boilers, heat pump, photovoltaic).

In these years, the cooling systems with tubes embedded in the slabs and walls became common also in middle-Europe.

The increasing number of realizations not only was a solid proof of the efficiency of this solution but allowed also to refine the theoretical approach for the regulation improving it with solutions that initially appeared to be not feasible or effective.

In 2005 the demand of radiant systems was increased by 36% (ref. [2])

In 2010 the construction of two new buildings equipped with modern radiant conditioning system was started: “Pearl River Tower” in Guangzhou, China, (71 storeys) and “Manitoba Hydro Office Tower” in Canada (22 storeys). The latter became the most energy efficient building in North America [site (34)].

In these years TABS got the definitive consecration as one of the best solutions to increase both energy sustainability and comfort in buildings (Figure 24 through Figure 27).

Figure 25: Schematic of PVC piping layout for TABS (source: ref. [56])

|

||

Figure 26: Comfort from thermally activated surfaces [source: site (50)]

|

Conclusions

The success gained till now suggests that the TABS have a high potential to be the future technology for heating and cooling of residential and commercial rooms, considering that the progressive increasing use of renewable sources and low exergy systems amplifies the benefits offered by these systems. The recent norm ISO 11855-4:15, replacing EN 15377-3:2008, specifically deals with TABS. These systems are also attractive to reach the European Union goals on the energy transition.

All the above is of course applicable to new buildings. It remains, however, that the national building heritage includes still operating floor heating plants according to the old solution (fifties) which, even though used with a lower service temperature than initially, because of the diffused use of condensation boilers and the improvement of building envelope insulation, are still affected by many issues of the past: lack of underneath thermal insulation, too deep embedment, metallic material inevitably damaged (for those never replaced), excessive thermal inertia, difficult automatic regulation because of the high response time. The best management of these old plants (obsolete as per construction aspects, modern as per concept) is a goal not easily reachable, which require specific ways of action.

Bibliography

- History of Radiant Heating & Cooling Systems – Part 1: Asia, di Robert Bean, Bjarne W. Olesen, Kwang Woo Kim – ASHRAE Journal, January 2010, ashrae.org

- History of Radiant Heating & Cooling Systems – Part 2: Europe, di Robert Bean, Bjarne W. Olesen, Kwang Woo Kim – ASHRAE Journal, February 2010, ashrae.org

- Idraulica n. 9 – Impianti a pannelli radianti, la regolazione e la distribuzione – Caleffi, 02.95 (>>)

- Idraulica n. 21 – Gli impianti a pannelli - Caleffi, 12.2001 (>>)

- Gli impianti a pannelli radianti, di Mario Doninelli – Caleffi, Quaderno n. 4 (>>)

- Sulla termotecnica in epoca romana – di F.R. D'Ambrosio, A. Chidichimo, F. Sorrentino – Storia dell’Ingegneria, 2006

- Sergius Orata: Inventor of the hypocaust? – by Garrett G. Fagan – Phoenix, Vol. 50, No. 1, 1996 (>>)

- Urban Conservation and Area Development in Afghanistan, pp. 10-12 - Aga Khan Historic Cities Programme – 2007 (>>)

- From Polis to Madina: Urban Change in Late Antique and Early Islamic Syria – by Hugh Kennedy – Oxford Journals, The Past and Present Society, 2005 (>>)

- Architectural Correlation Analysis of the Hammams of Cherchell (Algeria): Linear vs. Aggregate Space in the Traditional Bath – by Youcef Chennaoui – 2009 Archnet IJAR Volume 3 Issue 1, March 2009 (>>)

- Il riscaldamento a pavimento “ipocausto” fu inventato dai Greci e reso popolare dai Romani – di Matteo Rubboli – VM Vanilla Magazine (>>)

- A designer’s guide to underfloor heating in sports halls – Facility Report 02 – Sportscotland, 2008 (>>)

- Radiant Heating – by Adlam, Napier T. – The Industrial Press, 1947 (>>)

- Early Application of Engineering to the Warming of Buildings, by Dufton, A. F. – Transactions of the Newcomen Society, January 1940 (>>)

- Radiant Heating – by Shoemaker Richard Woolsey – McGraw-Hill Book Company, 1948 (>>)

- Radiant Heating and Cooling Handbook - by Watson R. and Chapman K. - McGraw-Hill, 2004 (>>)

- Central Heating and Forced Ventilation: Origins and Effects on Architectural Design – by Robert Bruegmann – Journal of the Society of Architectural Historians, Vol. 37, No. 3, pp. 143-160, October 1978. (>>)

- Kalendarium Hortense, or the Gard'ners Almanac, n.p., 169I, I34. Quatramere de Quincy, Architecture: Encyclopédie d'Architecture, 3 vols., Paris, 1788-1825,1,151, 638 (>>)

- Encyclopédie méthodique d’Architecture – Paris, 1788-1825, Vol. 1 (>>)

- Plans, Elevations, Sections and Perspective Views of the Gardens and Buildings at Kew in Surey – by William Chambers - London, 1763, pl. vii (>>) (>>)

- A Manual of Cottage Gardening, Husbandry, and Architecture – by J.C. Loudon - London, 1830 (>>)

- Supplement to Loudon’s Manual of Cottage Gardening, Husbandry, and Architecture – by J. Robertson - London, 1833 (>>)

- Sanitary Principles of School Construction - by Edwin Chadwick - Journal of the Royal Society of Arts, XIX, 1871, pp. 856-860 (>>)

- Healthy Hospitals - by Douglas Galton - Oxford, 1893 (>>)

- Béton in combination with iron as a building material - by W. E. Ward – Transactions of the American Society of Mechanical Engineers, Vol. IV, November 1882 and June 1883, pp. 388 ÷ 403 (>>)

- ASHRAE Illinois Chapter – Innovation and Its Role in the Evolution of Radiant Heating and Cooling Systems – by Brian M. Ford, SGL Group, November 12, 2013 - Monthly Meeting, (>>)

- Arthur Henry Barker – by EurIng Brian Roberts, CIBSE Heritage Group (>>)

- Barker on Heating – The Theory and Practice of Heating and Ventilation – by Arthur H. Barker – The Carton Press, London, 1912 (>>)

- Graphical Calculus – by Arthur H. Barker (>>) (>>)

- Graphic Methods of Engine Design: Including a Graphical Treatment of the Balancing Engines – by Arthur H. Barker (>>)

- Patent US1671568 – Heating and Cooling Device for Buildings – Arthur Henry Barker, May 29, 1928 (>>)

- Patent US1775152 – Heating Device for Building – Arthur Henry Barker, September 9, 1930 (>>)

- Radiant Heating with National Pipe – Bulletin n° 19 – United States Steel, 1951 (>>)

- Automatic Control of Radiant Panel Heating – Honeywell Control Systems, 1946 (>>)

- B & G Hydro-Flo Radiant heating – Bell & Gossett, 1945 (>>)

- Capture the sun with Hydro-Flo heating – Bell & Gossett, 1947 (>>)

- Odyssey of an Engineering Researcher – by Ken Rush – Engineering History Paper no. 15 – The Engineering Institute of Canada, 1997 (>>)

- Radiant Heating in the U.S. by Joseph F. Kern Jr - Heating and Ventilating. Volume 38, Number 3, March 1941 (>>)

- Radiant Heating by Copper & Brass Research Association – 1949 (>>)

- Plastic Pipe: It is Practical for Panel Heating? – Domestic Engineering, 1957 (>>)

- Byers Wrought Iron for Radiant Heating – A.M. Byers Company, 1944 (>>) (>>)

- Radiant or Panel Heat for Brooding Chicks by Henderson, D.C. – Poultry Science, Volume 29, Issue 2, 1 March 1950, pages 299-304 (>>)

- Brass and Copper in your home Radiant Heating – Chase Brass & Copper Co – 1950 (>>)

- Zurn Radiant Heating Design and Application Guide – Zurn (>>)

- Giacomini Radiant Systems (>>)

- RATHE Associates – Radiant Heating Systems, Complete Design & Installation Guide (>>)

- Radiant Heating and Cooling and Measured Home Performance for California Homes – Energy Research and Development Division, Final Project Report – GTI, June 2013 (>>)

- ROTH – Radiant heating Installation Manual for Residential and Commercial Installations – Roth, 2008

- Rayduct – The Pipe for Radiant Heating – Bethlehem Steel Company – Booklet 225-A (>>)

- Improving Process Heating System Performance – A Sourcebook for Industry – Second Edition – Industrial Technologies Program, 2007 (>>)

- Smoke Flow in Chinese Kangs – by Zhi Zhuang, Yuguo Li and Bin Chen – Indoor and Built Environment – 2009; 18; 3:219-233 (>>)

- Thermally Activated Building System (TABS): Efficient Cooling and heating of commercial buildings – by Georgios Vagiannis, Uponor Corporation – Conference Climamed, September 2015 (>>)

- Thermally activated building systems (TABS): Energy efficiency as a function of control strategy, hydronic circuit topology and (cold) generation system – by B.Lehmann, V.Dorer, M.Gwerder, F.Renggli, J.Tödtli – Applied Energy, Volume 88, Issue 1, January 2011, Pages 180-191 >>)

- Control of thermally-activated building systems (TABS) – by M. Gwerder, B. Lehmann, J. Tödtli, V. Dorer, F. Renggli – Applied Energy, Volume 85, Issue 7, July 2008, Pages 565-581. (>>)

- Prof. Marco Carlo Masoero, Politecnico di Torino, Energy storage in urban multi-energy systems, ICARB Workshop, 2014 (>>)

- Application of water flowing PVC pipe and EPS foam bead as insulation for wall panel – by Ali, Umi Nadiah, Nor, Norazman Mohamad, Yusuf, Mohammed Alias, Othman, Maidiana, Yahya, Muhamad Azani - AIP Conference Proceedings [Author(s) INTERNATIONAL CONFERENCE ON ENGINEERING AND TECHNOLOGY (IntCET 2017) - Putrajaya, Malaysia (23–24 November 2017)] (>>)

- Uponor – Thermally Active Building Systems – Brochure, 08/10 (>>)

- Thermally Active Surfaces in Architecture – by Kiel Moe – Princeton Architectural Press, 2010 (>>)

- ISO 11855 - The international Standard on the Design, dimensioning, installation and control of embedded radiant heating and cooling systems – by Jae-Han Lim and Kwang-Woo Kim – REHVA Journal, 01/2016 (>>)

- Hot Water Heating and Radiant Heating and Radiant Cooling – F.E. Giesecke – Technical Book Company, 1946 (>>)

- Thermo Active Building Systems Using Building Mass to Heat and Cool – by Bjorne W. Olesen, ASHRAE Journal, February 2012 (>>)

- A novel classification scheme for design and control of radiant system based on thermal response time – by Ning, Baisong; Schiavon, Stefano; Bauman, Fred S – Energy and Buildings, Volume 137, 15 February 2017, pages 39-45 (>>)

- Observations on the Construction of Healthy Dwellings, namely Houses, Hospitals, Barracks, Asylums, etc. - by Douglas Galton – Oxford at the Clarendon Press, 1830 (>>)

Websites

- Riscaldamento a pavimento – Storia del riscaldamento a pavimento: dalle origini fino ai giorni nostri (>>) (consulted on 2021-01-08)

- Idraulica Piatti – Riscaldamento a pavimento (www.idraulicapiatti.net) (>>) (consulted on 2021-01-08)

- Studio Mercattili (www.studiomercattili.it) – Riscaldamento a pavimento (>>) (consulted on 2021-01-08)

- Lovama impianti – Riscaldamento a pavimento: cenni storici (>>) (consulted on 2021-01-08)

- Wikipedia – Ipocausto (>>) (consulted on 2021-01-08)

- Imperium Romanum – Il riscaldamento dei romani (>>) (consulted on 2021-01-08)

- Il riscaldamento nelle residenze dell’antica Roma: braciere e ipocausto nelle ville, nelle domus e nelle insulae – Apros Blog, 10.09.2018 (>>) (consulted on 2021-01-08)

- Wikipedia – Hypocaustum (>>) (consulted on 2021-01-08)

- MAD051 Blog - Breve storia del riscaldamento – 13 febbraio 2017 (>>) (consulted on 2021-01-08)

- The Romans in Britain – Roman Central Heating (consulted on 2021-01-08) (>>)

- The History of Underfloor Heating Systems (consulted on 201-01-08) (>>)

- Wikipedia – Ondol (>>) (consulted on 2021-01-11)

- Ondol (Korean Home Heating System) – an ancient heating system lasting millennia (>>) (consulted on 2021-01-11)

- Wikipedia – Kang bed stove (>>) (consulted on 2021-01-11)

- Oldhouse – A look at radiant heating systems (>>) (consulted on 2021-01-11)

- Wikipedia - Underfloor Heating (consulted on 2021-01-11) (>>)

- Wikipedia – Radiant heating and cooling (>>) (consulted on 2021-01-11)

- Radiant Panel Association, RPA (>>) (consulted on 2021-01-12)

- U.S. Energy Department – Radiant Heating (>>) (consulted on 2021-01-12)

- AMETHERM - Thermal Time Constant and NTC Thermistors: A Practical Study (>>) (consulted on 2021-01-12)

- Radiant & Hydronics - A Brief History of Radiant Heating (>>) (consulted on 2021-01-12)

- HeatingHealp.com - The Secrets of Heating Old Churches – by Dan Holohan, June 9, 2015 (consulted on 2021-01-12) (>>)

- WarmlyYours – What is Radiant Floor Heating? (consulted on 2021-01-12) (>>)

- RADIANT&HYDRONICS – A Brief History of Radiant heating – by Steve Smith and Jack Sweet, June 1, 2006 (consulted on 2021-01-12) (>>)

- Warmyyourfloor – The History of Radiant Floor Heating – March 24, 2015 (consulted on 2021-01-12) (>>)

- Wikipedia – Radiant Heating (consulted on 2021-01-12) (>>)

- HeatingHealp.com - Levittown Radiant Heating Systems – by Dan Holohan, June 23, 2014 (consulted on 2021-01-12) (>>)

- Plumbing Perspective – Frank Lloyd Wright House; Relocated and Reacquainted With Radiant – June 21, 2016 (>>) (consulted on 2021-01-23)

- Wikipedia – Usonia (>>) (consulted on 2021-01-23)

- Wikipedia – Frank Lloyd Wright (EN: >>) (IT: >>) (accesso del 2021-01-23)

- Wikipedia – William Levitt (EN: >>) (accesso del 2021-01-23)

- Wikipedia – Levittown (IT: >>) (EN: >>) (accesso del 2021-02-06)

- Thermo-Floor – The History of Underfloor Heating (>>) (accesso del 2021-02-06)

- Healthy Heating – History of radiant heating and cooling – A chronological review – by Robert Bean, 2010 (accesso del 2021-02-10) (>>)

- Richard Crittal and Co - Grace’s Guide to British Industrial History – 20 March 2017 (>>) (consulted on 2021-02-11)

- RCM Products (consulted on 2021-02-11) (>>)

- Floor Heating System in Chase, MI – Floor Heating Leaders (consulted on 2021-02-11) (>>)

- Wikipedia - Bethlehem Steel (consulted on 2021-02-11) (>>)

- Wikipedia - Chase Brass and Copper Company (consulted on 2021-02-11) (>>)

- A.M. Byers Company – MyCompanies Wiki (consulted on 2021-02-11) (>>)

- AO Smith – Web site (consulted on 2021-02-11) (>>)

- Wikipedia - Franklin Stove (consulted on 2021-02-11) (>>)

- Wikipedia - Angier March Perkins (consulted on 2021-02-11) (>>)

- Uponor – web Site (consulted on 2021-02-11) (>>)

- Radiant Floor Heating Europe Market: Complete Analytical Report for 2021 (consulted on 2021-02-11) (>>)

- Healthy Heating - Radiant Mythology: How myths about low temperature radiant heating and high temperature radiant cooling get spread. Copyright 2004-2016, Robert Bean, R.E.T., P.L.(Eng.) All Rights Reserved (consulted on 2021-02-11) (>>)

- Uponor – Thermally Active Building Systems Explained – by Robert Cubick, July 29, 2016 (consulted on 2021-02-12) (>>)

- State of Green – Thermal Active Building System (TABS) (consulted on 2021-02-12) (>>)

- Positive Energy – Texas’ First Radiant cooling & Heating System (That We Know Of) – May 23, 2017 (>>) (consuted on 2021-02-19)

- Thermally Active Surfaces – October 22, 2012 (>>) (consuted on 2021-02-19)

- The Body and Thermal Comfort – October 29, 2012 (consuted on 2021-02-19) (>>)

- Plumbing & mechanical Engineer – Back to Basics: A Study of Heat Transfer, Pipe to Pipe – April 3, 2003 (consuted on 2021-02-19) (>>)

- Ingenio - Sistemi radianti annegati, la revisione della norma UNI EN 1264: focus sui principali temi in discussione – 5/11/2020 (consuted on 2021-02-19) (>>)

- Ingenio - Nuova UNI EN 1264 in pubblicazione nel 2021: progettazione, test e installazione dei sistemi radianti annegati – 21/12/2020 (consuted on 2021-02-19) (>>)

- Wikipedia - Jacob Perkins (>>) (consuted on 2021-02-19)

Commenti

Alice.Zhao (non verificato)

Mar, 28/06/2022 - 10:20

Collegamento permanente

Hey

Pagine

Aggiungi un commento